- Inicio

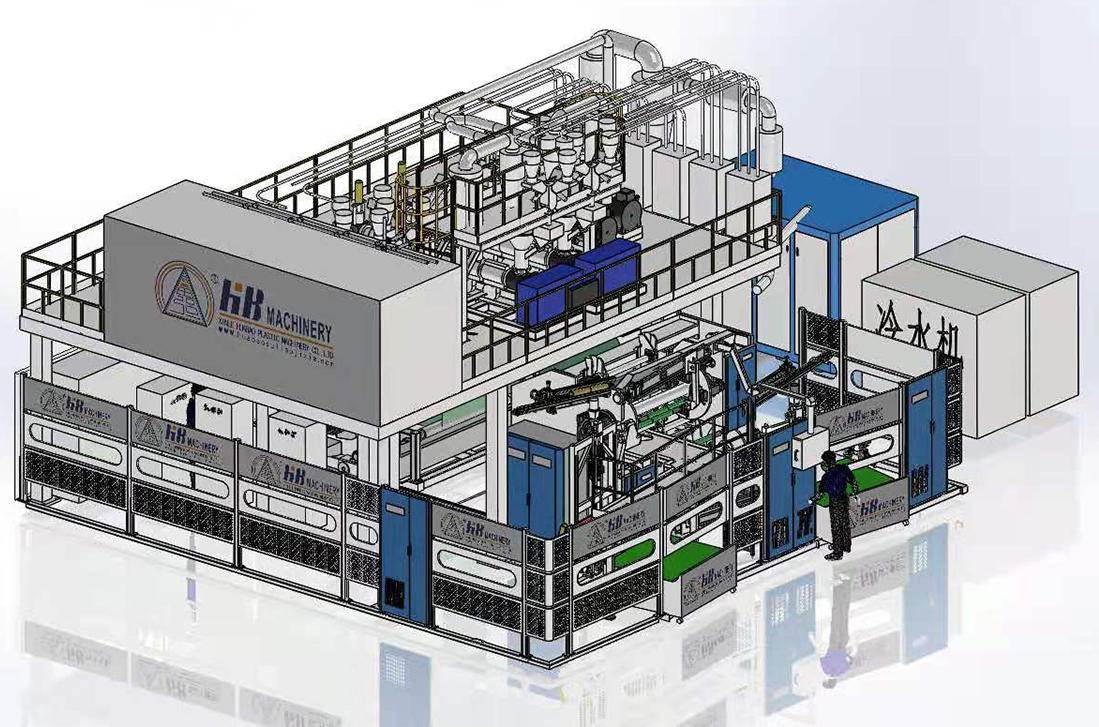

- Línea de películas fundidas

Línea de películas fundidas

Our knowledge and expertise along with years of experience allows us to respond quickly with solutions tailored to your needs of cast film production. At HB Machinery, every unit of cast film line can be engineered and retrofitted to entirely fulfill your specific needs.

-

-

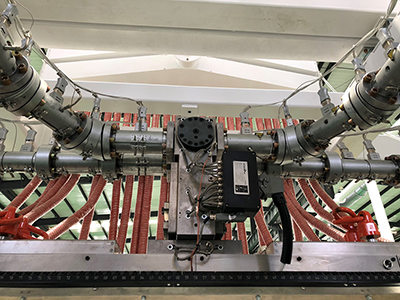

- Extruder The extruders for cast film are typically designed to meet the specific characteristics of the extruded materials and processing requirements. According to the size of extruder and processed materials, the screws can be provided with armoured flights for a better performance of wear resistance.

-

-

-

- Winding System The winding system is designed with functions of trimming, embossing and slitting. We provide various winding systems with optimization focused on the aspect of automation to meet customers’ needs. All of these winders feature robust steel structure which can reduce vibrations produced by dynamic forces during the production process at high speed.

-

-

- Línea de película fundida para CPP / CPEThis cast film line is primarily used to produce multilayer (three-layer or five-layer) co-extruded CPP and CEVA films, as well as PA/EVOH high barrier films.

-

- Línea de película CPEThe cast film line utilizes LLDPE/ MLLDPE/LDPE/HDPE as base material to produce multilayer co-extruded CPE film with high transparency.

-

- Línea de película retráctil de PVCPVC transparent Packing Film Line uses PVC compounded material that is fully mixed with recipe components to produce various high quality clear films and embossed films, a wide broad of specifications is available per customers’ requirements.

Desde su creación en el año 1998, HB Machinery ha sido reconocido como un fabricante líder de líneas de películas fundidas. Nuestras líneas de extrusión de películas y láminas fundidas se aplican en amplia variedad de industrias, incluyendo el envasado de alimentos, productos farmacéuticos, suministros de construcción, manipulación de materiales. Nuestra gran experiencia y profesionalismo nos han llevado a proporcionar amplia gama de líneas de extrusión de película fundida, así como máquinas de extrusión de láminas de plástico para satisfacer las necesidades de nuestros clientes. Contribuimos al desarrollo sostenible del sistema de extrusión de película fundida para satisfacer las necesidades de los clientes en envases flexibles y otras aplicaciones.

- No.136 Nanhuan Road, Xinle City, Hebei Province +86-311-85196308 +86-311-85196310